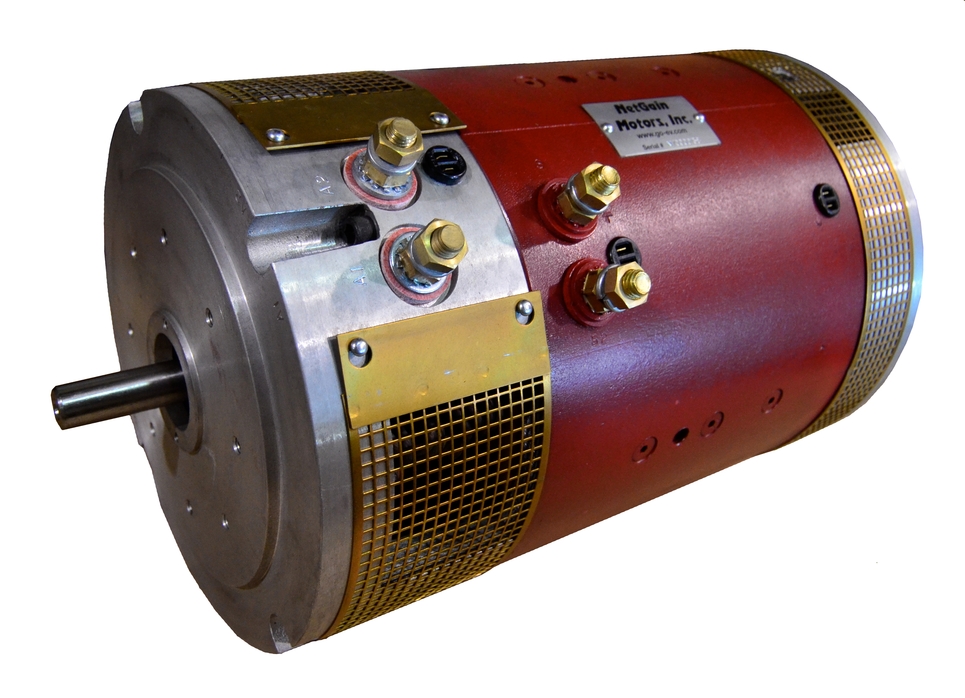

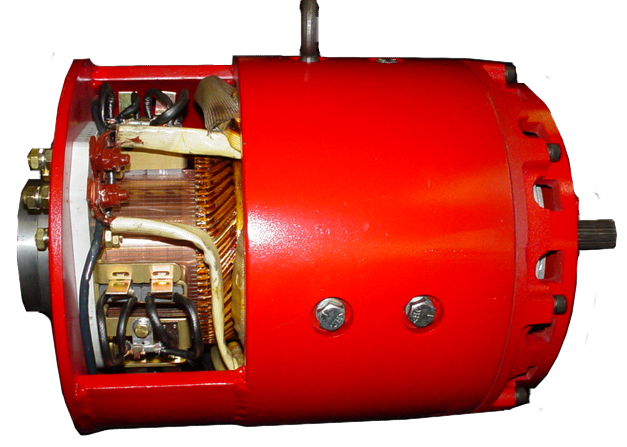

These motors have a 7.25" frame diameter. They are series wound brushed DC motors. Both motors have double ended shafts. Our WarP 7™ motor has been designed for use in dual motor applications and to ease the conversion process for people who want dual motors and/or direct drive applications. These motors have many unique features that set them apart from any other brushed DC EV motor currently manufactured.

Delivery Time: From Stock

Unique advantages of WarP 7™ & TransWarP 7™ Motors:

- Timing can be adjusted to CWDE or CCWDE(from the normal Neutral).

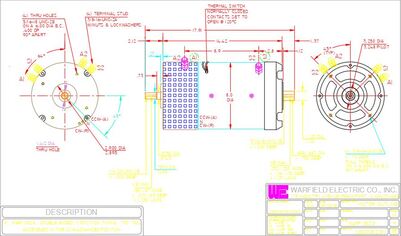

- The WarP 7™ Drive End (DE) shaft and the Commutator End (CE) shaft are 1.125" in diameter with a 1/4" keyway.

- The WarP 7™ is not the typical 1.125" single-keyed type, but rather a hefty 1.370" shaft with a 32-tooth involute spline that is identical to the tail shaft spline of a Turbo 400 transmission. The Commutator End (CE) shaft is 1.125" in diameter with a 1/4" keyway that will match with the WarP 7™ Drive End (DE) shaft.

- These motors have brush wear indicators and a temperature snap switch.

- They have high efficiency fans and massive commutators and brushes.

- The TransWarP 7™ motor uses an optional "shorty" tail shaft housing from a Chevrolet Turbo 400 transmission fitted to the drive end-bell (may be ordered with or without housing!) This motor was originally designed to be coupled directly to a drive shaft!

- We have added double wide bearings on the drive end of the TransWarP 7™ motor, and we've added grease fittings (as you now have a slip-yoke assembly...). We use the industry standard 1350 universal, so you can easily adapt it to any manufacturers drive shaft!

- We also made the commutator end shaft of the TransWarP 7™ motor the same diameter as the drive end of a typical WarP 7™ - just in case you wanted to connect 2, 7" motors together!

The Essentials:

- Type - Series wound DC

- Diameter - 7.125"

- Length - 16.62" (face-face)

- Weight - 86 lbs.

- HP - 18 (Continuous @ 144V)

- RPM - 7,300 peak / 5,500 continuous

- Torque - 50 lb-ft @ 345 Amps

- Shaft - Double or single ended

- Timing - Favored or neutral (User selectable)

- Mounting - Industry standard configuration

- Brushes - Helwig Carbon

- Insulation - Class "H"

- Terminal Studs - 3/8"

- Fan - High efficiency 15 blade

- Delivery - Special Order

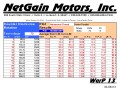

Performance Data:

72V Advanced Data

72V Advanced Data

48V Advanced Data

48V Advanced Data

48V Neutral Data

48V Neutral Data

72V Advanced Graph

72V Advanced Graph

48V Advanced Graph

48V Advanced Graph

48V Neutral Graph

48V Neutral Graph

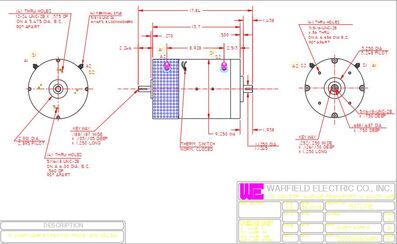

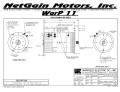

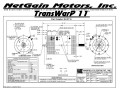

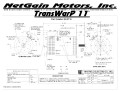

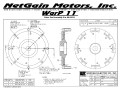

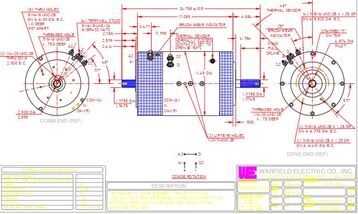

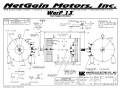

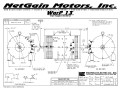

Engineering Drawings:

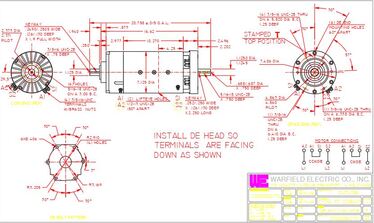

TransWarP 7 Drive End

TransWarP 7 Drive End

TransWarP 7 Comm End

TransWarP 7 Comm End

TransWarP 7 (00-08217)

TransWarP 7 (00-08217)

Retail Price List

Retail Price List  WarP 7™ Sales Sheet

WarP 7™ Sales Sheet  CAD Drawings

CAD Drawings

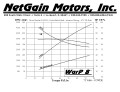

Performance Graph

Performance Graph Performance Data

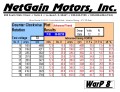

Performance Data WarP 8 (00-08200)

WarP 8 (00-08200) WarP 8 (00-08203)

WarP 8 (00-08203) WarP 8 (00-08206)

WarP 8 (00-08206) WarP 8 (00-08218)

WarP 8 (00-08218) WarP 8™ Sales Sheet

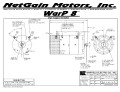

WarP 8™ Sales Sheet CAD Drawings

CAD Drawings

Performance Graph

Performance Graph Performance Data

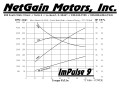

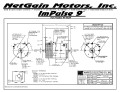

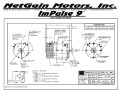

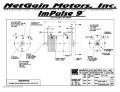

Performance Data ImPulse 9 (00-08259NA)

ImPulse 9 (00-08259NA) ImPulse 9 (00-08269)

ImPulse 9 (00-08269) ImPulse 9 (00-08249)

ImPulse 9 (00-08249) ImPulse 9™ Sales Sheet

ImPulse 9™ Sales Sheet TransPulse 9™ Sales Sheet

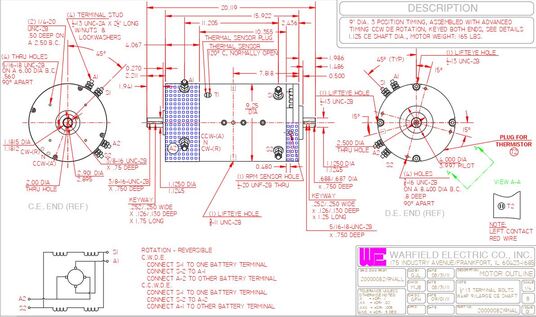

TransPulse 9™ Sales Sheet CAD Drawings

CAD Drawings

Performance Graph Mfg Prior 7/1/2010

Performance Graph Mfg Prior 7/1/2010 TransWarP 9 Performance Graph

TransWarP 9 Performance Graph Performance Data Mfg Prior 7/1/2010

Performance Data Mfg Prior 7/1/2010 TransWarP 9 Performance Data

TransWarP 9 Performance Data WarP 9 Mfg Prior 7/1/2010

WarP 9 Mfg Prior 7/1/2010 TransWarP 9

TransWarP 9 WarP 9™ Sales Sheet

WarP 9™ Sales Sheet TransWarP 9™ Sales Sheet

TransWarP 9™ Sales Sheet CAD Drawings

CAD Drawings

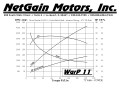

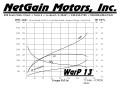

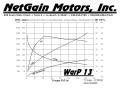

WarP 11 Performance Graph

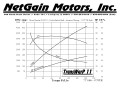

WarP 11 Performance Graph TransWarP 11 Performance Graph

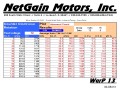

TransWarP 11 Performance Graph WarP 11 Performance Data

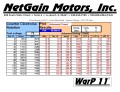

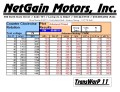

WarP 11 Performance Data TransWarP 11 Performance Data

TransWarP 11 Performance Data WarP 11 Mfg Prior 7/1/2012

WarP 11 Mfg Prior 7/1/2012 WarP 11 (00-08811)

WarP 11 (00-08811) TransWarP 11 Mfg Prior 9/1/2006

TransWarP 11 Mfg Prior 9/1/2006 TransWarP 11 Mfg After 9/1/2006

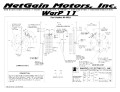

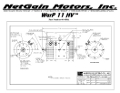

TransWarP 11 Mfg After 9/1/2006 WarP 11 Drive End

WarP 11 Drive End WarP 11™ Sales Sheet

WarP 11™ Sales Sheet TransWarP 11™ Sales Sheet

TransWarP 11™ Sales Sheet CAD Drawings

CAD Drawings

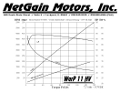

WarP 11HV Performance Graph

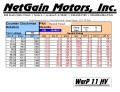

WarP 11HV Performance Graph WarP 11HV Performance Data

WarP 11HV Performance Data WarP 11HV

WarP 11HV

WarP 13 Serial Performance Graph

WarP 13 Serial Performance Graph WarP 13 Parallel Performance Graph

WarP 13 Parallel Performance Graph WarP 13 Serial Performance Data

WarP 13 Serial Performance Data WarP 13 Parallel Performance Data

WarP 13 Parallel Performance Data WarP 13 (00-08413)

WarP 13 (00-08413) WarP 13 (00-08513)

WarP 13 (00-08513) DC End User Manual

DC End User Manual