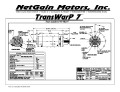

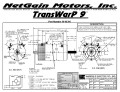

This motor has an 7.25" diameter. It is a series wound DC motor with a double ended shaft.

Our TransWarP 7 ™

Motor has been designed for use in EMIS applications and to ease the conversion process for people who want dual motor and/or direct drive applications. It has many unique features that set it apart from any other EV motor currently manufactured.

Timing can be adjusted to CWDE (from the normal CCWDE).

This motor has a "shorty" tail shaft housing from a Chevrolet Turbo 400 transmission fitted to the drive end-bell (may be ordered with or without housing!) This is because the drive end shaft is not the typical 1.125" single-keyed type, but rather a hefty 1.370", 32-tooth involute spline that is identical to the tail shaft spline of a Turbo 400 transmission. In other words, this motor was designed to replace a transmission and couple directly to a drive shaft!

We have added grease fittings (as you now have a slip-yoke assembly...). We use the industry standard 1350 universal, so you can easily adapt it to any manufacturers drive shaft! The motor also has brush wear indicators and a temperature snap switch. It has the same high efficiency fan and massive commutator and brushes as the WarP 7 ™

Retail Price List

Delivery Time: From Stock.

TOP

DOWNLOAD CAD DRAWINGS

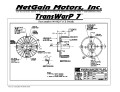

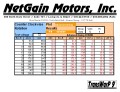

This motor has an 9.25" diameter. It is a series wound DC motor with a double ended shaft.

Our TransWarP 9 ™ motor has been designed to ease the conversion process for people who want dual motor and/or direct drive applications. It has many unique features that set it apart from any other EV motor currently manufactured.

This motor has a "shorty" tail shaft housing from a Chevrolet Turbo 400 transmission fitted to the drive end-bell (may be ordered with or without housing!) This is because the drive end shaft is not the typical 1.125" single-keyed type, but rather a hefty 1.370", 32-tooth involute spline that is identical to the tail shaft spline of a Turbo 400 transmission. In other words, this motor was designed to replace a transmission and couple directly to a drive shaft!

We have added double wide bearings on the drive end, added grease fittings (as you now have a slip-yoke assembly...). We use the industry standard 1350 universal, so you can easily adapt it to any manufacturers drive shaft! The motor also has brush wear indicators and a temperature snap switch. It has the same high efficiency fan and massive commutator and brushes as the WarP 9 motor. We even made the commutator end shaft the same diameter as the drive end of a typical WarP 9 - just in case you wanted to connect 2, 9" motors together!

We also provide 2 lifting holes.

Retail Price List

Delivery Time: From Stock.

TOP

DOWNLOAD CAD DRAWINGS

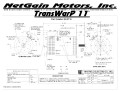

This motor has an 11.45" diameter. It is a series wound DC motor with a double ended shaft.

Our TransWarP 11 ™ Motor has been designed to ease the conversion process for people who want direct drive applications. It has many unique features that set it apart from any other EV motor currently manufactured.

This motor has a "shorty" tail shaft housing from a Chevrolet Turbo 400 transmission fitted to the drive end-bell (may be ordered with or without housing!) This is because the drive end shaft is not the typical 1.125" single-keyed type, but rather a hefty 1.370", 32-tooth involute spline that is identical to the tail shaft spline of a Turbo 400 transmission. In other words, this motor was designed to replace a transmission and couple directly to a drive shaft!

But we didn't stop there! We added double wide bearings on the drive end, added grease fittings (as you now have a slip-yoke assembly...). We chose the industry standard 1350 universal, so you can easily adapt it to any manufacturers drive shaft! We moved the terminals to the side of the motor to avoid road hazard damage, and to allow more clearance above and below. The motor also has brush wear indicators and a temperature snap switch. It has the same high efficiency fan and massive commutator and brushes as the WarP 11 motor. We even made the commutator end shaft the same diameter as the drive end of a typical WarP 11 - just in case you wanted to connect 2, 11" motors together!

If that wasn't enough, we also provide a lifting ring and 8 threaded mounting holes in the commutator end bell. This way you will find it easier to mount, as well as having a method of easily attaching a speed sensor, alternator, air conditioner, etc.

Retail Price List

Delivery Time: From Stock.

TOP

DOWNLOAD CAD DRAWINGS

TOP

DOWNLOAD CAD DRAWINGS

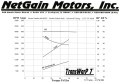

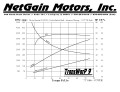

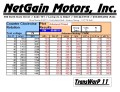

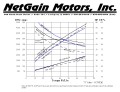

*Spreadsheet data is from actual dyno runs for the motors, the graphs

may not be 100% representative of the data due to plotting limitations

of the software used to produce the graphs. The

Warfield dyno is limited to 72 Volts and ~600 Amps - figures beyond

these points may be extrapolated. Most motor losses are fixed, so performance

extrapolated at higher currents will likely be slightly better than most

extrapolations.

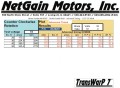

Now in stock!

TransWarP 7 ™ Motors

TransWarP 9 ™ Motors

TransWarP 11 ™ Motors