Version 1.0 -This project initially started out as a feasibility project which led to the development of the Bad Amplitude battery powered dragster. We started with an old Enduro Go Kart frame and removed the original Yamaha internal combustion engine. Next, John Spooner used his metal working skills to fabricate two battery boxes and added an adapter plate for a 96 Volt electric motor. He then installed an on/off switch and a contactor. The motor was rated at 3/4 HP and 1850 RPM's and used the original chain and gears. Karl Klien provided 18, 12 Volt batteries and Karl Klien also added body components. Version 1.0 of the Go Kart was born. These are images of the 1.0 version 96 Volt version of the Go Kart (2 parallel strings of 96 Volts).

Version 2.0 -At the urging of his son (Hunter - then 12 years old) George began the project of rebuilding the Go Kart ($350). Over the 3+ years the Go Kart sat neglected, the body pieces had disappeared. The rear axle was bent and also needed to be replaced ($20). George bought a Briggs & Stratton Etek motor ($325) and a Sevcon Millipaq 4QD controller ($350). (and the programming module ($175)...) This controller was chosen as it works well with the B&S motor, and because it provides regen when the throttle is released. Since the Etek turns 72 RPM per volt, various gearing combinations were purchased in order to maximize the various uses of the kart ($50). 160, 6-Volt sealed batteries (in case I needed some "spares") were purchased from HOBI International ($320). The frame was completely stripped, then sandblasted and finally powder coated metallic red with a clear coat ($400). John Emde fabricated a new motor mount that allows the motor to be "slid" forwards and backwards. This allows the chain to be tightened as well as redistributing the motor weight. The 6-Volt batteries have been installed in 3 parallel strings of 36 Volts. A 36 Volt battery charger was also purchased ($150). The battery rack is capable of holding 4 parallel strings of 48 Volts using the previous 12 Volt batteries. The chain was upgraded to #40 to handle the additional torque produced by the Briggs & Stratton motor. Miscellaneous parts (5K pot ($70), nuts, bolts, steering wheel ($30), upholstery ($75). Total anticipated cost when complete ~ $3000.00 (does not include labor....)

|

|

To request further information you may CLICK HERE, or to purchase a motor, please contact one of our Authorized Dealers or Authorized Distributors. |

| You may contact us directly via the following: |

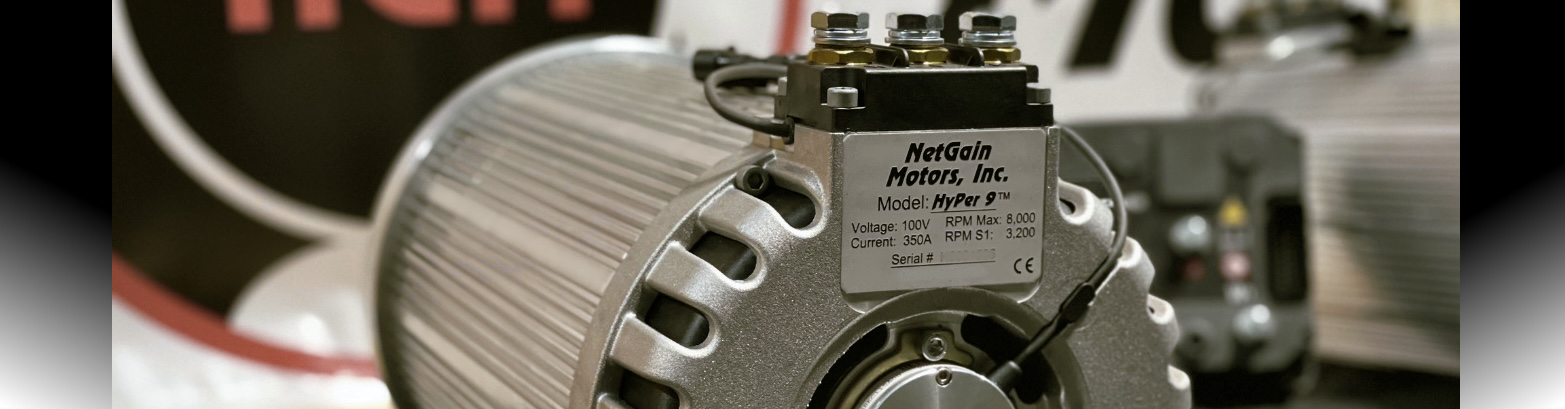

| NetGain Motors, Inc. |

|---|

| 800 South State Street, Suite 4 |

| Lockport, Illinois 60441 |

| Voice: 630-243-9100 |

| Fax: 630-685-4054 |

| Email: info@go-ev.com |

|

Problems with these web pages? Contact the person responsible for the problems!

Website Use Privacy Policy |